Chapter 15-Transition to Jet Powered Airplanes

Table of Contents

General

Jet Engine Basics

Operating the Jet Engine

Jet Engine Ignition

Continuous Ignition

Fuel Heaters

Setting Power

Thrust to Thrust Lever Relationship

Variation of Thrust with RPM

Slow Acceleration of the Jet Engine

Jet Engine Efficiency

Absence of Propeller Effect

Absence of Propeller Slipstream

Absence of Propeller Drag

Speed Margins

Recovery from Overspeed Conditions

Mach Buffet Boundaries

Low Speed Flight

Stalls

Drag Devices

Thrust Reversers

Pilot Sensations in Jet Flying

Jet Airplane Takeoff and Climb

V-Speeds

Pre-Takeoff Procedures

Takeoff Roll

Rotation and Lift-Off

Initial Climb

Jet Airplane Approach and Landing

Landing Requirements

Landing Speeds

Significant Differences

The Stabilized Approach

Approach Speed

Glidepath Control

The Flare

Touchdown and Rollout

THRUST TO THRUST LEVER RELATIONSHIP

In a piston engine propeller driven airplane, thrust is proportional to r.p.m., manifold pressure, and propeller blade angle, with manifold pressure being the most dominant factor. At a constant r.p.m., thrust is proportional to throttle lever position. In a jet engine, however, thrust is quite disproportional to thrust lever position. This is an important difference that the pilot transitioning into jet powered airplanes must become accustomed to.

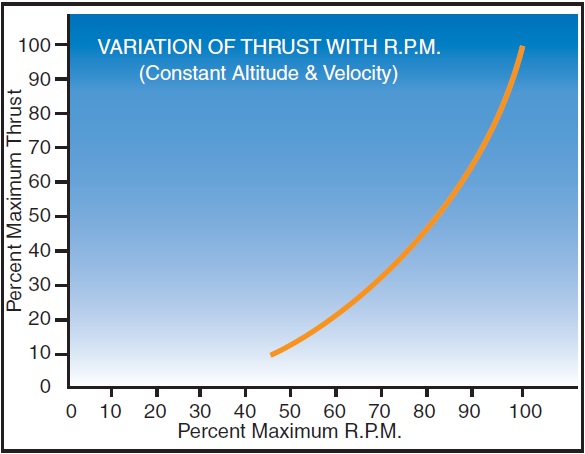

On a jet engine, thrust is proportional to r.p.m. (mass flow) and temperature (fuel/air ratio). These are matched and a further variation of thrust results from the compressor efficiency at varying r.p.m. The jet engine is most efficient at high r.p.m., where the engine is designed to be operated most of the time. As r.p.m. increases, mass flow, temperature, and efficiency also increase. Therefore, much more thrust is produced per increment of throttle movement near the top of the range than near the bottom.

One thing that will seem different to the piston pilot transitioning into jet powered airplanes is the rather large amount of thrust lever movement between the flight idle position and full power as compared to the small amount of movement of the throttle in the piston engine. For instance, an inch of throttle movement on a piston may be worth 400 horsepower wherever the throttle may be. On a jet, an inch of thrust lever movement at a low r.p.m. may be worth only 200 pounds of thrust, but at a high r.p.m. that same inch of movement might amount to closer to 2,000 pounds of thrust. Because of this, in a situation where significantly more thrust is needed and the jet engine is at low r.p.m., it will not do much good to merely ôinch the thrust lever forward.ö Substantial thrust lever movement is in order. This is not to say that rough or abrupt thrust lever action is standard operating procedure. If the power setting is already high, it may take only a small amount of movement. However, there are two characteristics of the jet engine that work against the normal habits of the piston engine pilot. One is the variation of thrust with r.p.m., and the other is the relatively slow acceleration of the jet engine.

VARIATION OF THRUST WITH RPM

Whereas piston engines normally operate in the range of 40 percent to 70 percent of available r.p.m., jets operate most efficiently in the 85 percent to 100 percent range, with a flight idle r.p.m. of 50 percent to 60 percent. The range from 90 percent to 100 percent in jets may produce as much thrust as the total available at 70 percent. [Figure 15-6]

Figure 15-6. Variation of thrust with r.p.m.

PED Publication